How we build the tunnels

Customer Service Monday to Friday 8 a.m. to 4 p.m.For traffic information and issues that requires immediate attention, we are open all hours.

Tel: +46 (0)771 921 921

The E4 Stockholm Bypass goes primarily through rock of good quality. The quality of the rock notwithstanding, it is injected with cement-based sealant before the subsequent blasting. This technique prevents ground water from entering the tunnel and the lowering of the ground water level. Then the tunnel itself is blasted out with a traditional drill and blast method.

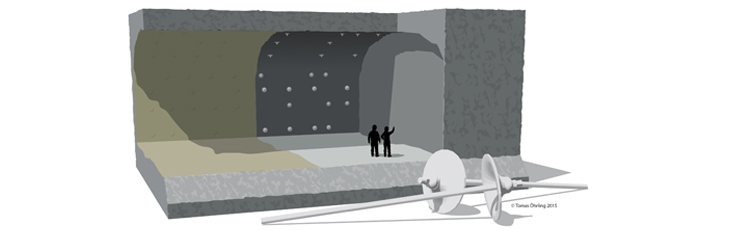

Blasting and building a tunnel is called driving a tunnel or tunnel driving. The tunnel is driven forward in cycles consisting of seven steps in each cycle. We drive the tunnel forward 5-15 metres per week by repeating the steps.

Tunnel driving – seven steps through the rock

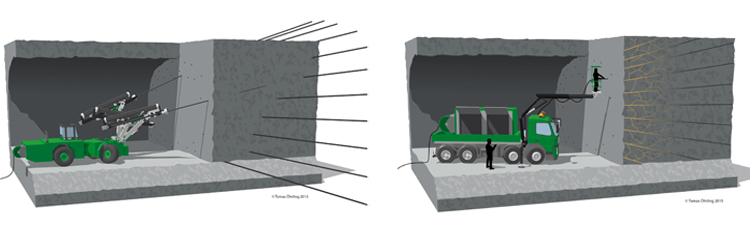

1. Drilling for injection

In order to avoid water leakage, we seal the rock's natural cracks. It is called injection.

Holes are drilled to a length of 20-25 metres obliquely in a ring around the tunnel. A mixture of cement and water is forced into the bore holes under high pressure and out through the cracks in the rock. The cement hardens and thereby seals the rock around the future tunnel. Water leakage can influence both the tunnel and the surroundings.

2. Drilling

The next step is to drill the actual blasting holes. Using a computer-guided drilling rig, the bore holes are positioned precisely and with the correct length.

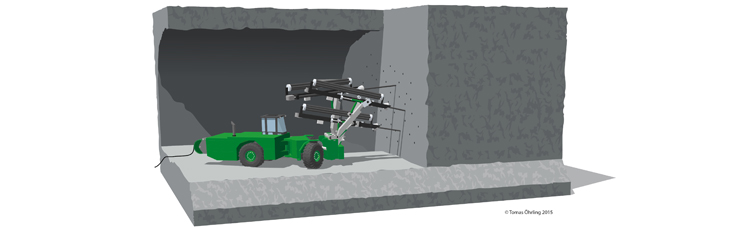

3. Charging

We charge the hole with blasting agent that is pumped into the bore holes using a charging vehicle. The blasting agent consists of multiple components that we mix together with the charge. This renders the blasting agent explosive. The charges are connected together in a specific sequence in order to detonate in the right order. This controlled blast makes it is possible to blast carefully and gently for the surrounding rock.

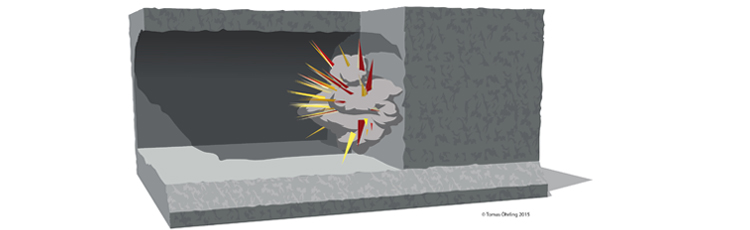

4. Blasting

The rock is blasted out after the charging. The amount of blasting agent is adapted to the surroundings. In densely populated areas, for example, the blasting salvoes are smaller. Small blasting salvoes reduce vibrations, but they make the tunnel driving process slower

5. Unloading

Whilst the Stockholm Bypass is built, more than 19 million tonnes of rock must be transported away from the tunnels. The blasted and crushed rock is a raw material that will be used in the construction of the Stockholm Bypass and in other construction projects in the region.

Roughly half of the rock from the Stockholm Bypass tunnels will be transported away by boat and the rest by lorry.

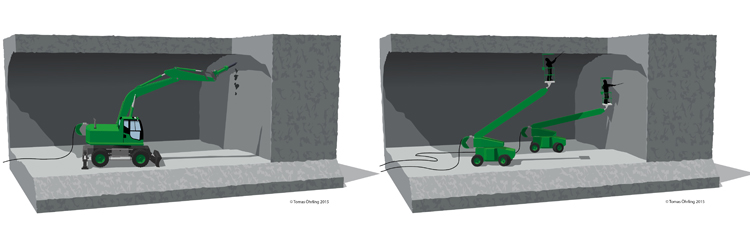

6. Scraping

We knock off all the loose rock from the tunnel ceiling and walls in a process called scraping. Mechanical scraping takes place first with a hydraulic hammer. Then the scraping is done manually.

We knock off all the loose rock from the tunnel ceiling and walls in a process called scraping. Mechanical scraping takes place first with a hydraulic hammer. Then the scraping is done manually.

7. Reinforcement

The tunnel is reinforced with rock bolts. The need for rock reinforcement varies along the route and depends on the quality of the rock. Then we spray the tunnel walls and ceiling with concrete. The reinforced tunnel is then clad with an inner wall and inner ceiling in order to create a dry tunnel environment.

The tunnel is reinforced with rock bolts. The need for rock reinforcement varies along the route and depends on the quality of the rock. Then we spray the tunnel walls and ceiling with concrete. The reinforced tunnel is then clad with an inner wall and inner ceiling in order to create a dry tunnel environment.

(Illustrated by: Tomas Öhrling, 2015)